Importance of Predictive Maintenance

Power transformers are among the most critical and expensive assets in

power distribution networks. Unexpected failures can cause grid

instability, heavy financial losses, and prolonged outages.

Predictive maintenance enables utilities to monitor transformer health

in real time using sensor-based data and AI analytics. Instead of

reacting after failure, maintenance teams can anticipate issues and

intervene before breakdown occurs.

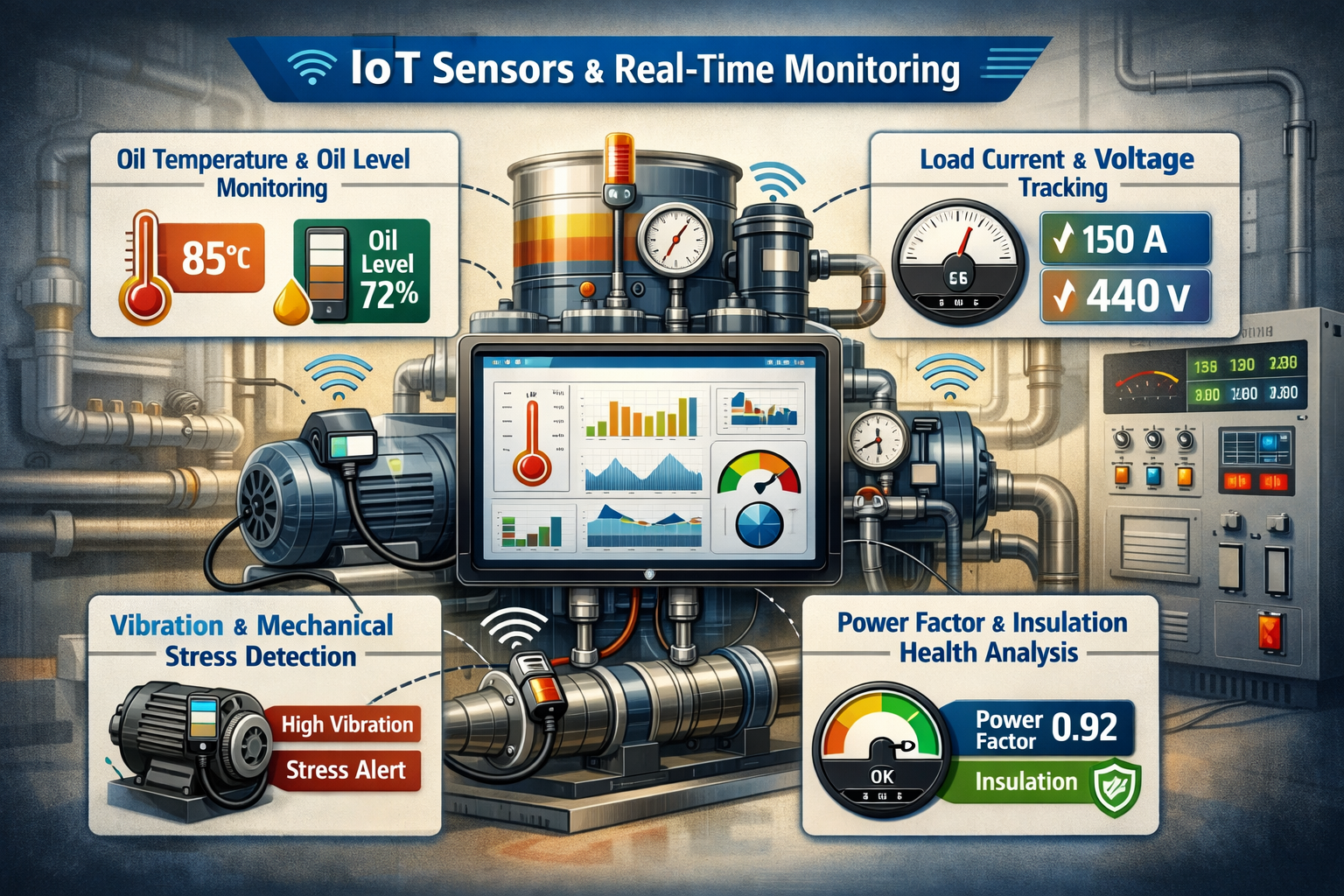

AI-Based Transformer Health Analytics

AI-driven platforms continuously analyze parameters such as oil

temperature, oil level, load current, voltage, vibration, and power

factor.

Machine learning models detect abnormal patterns like insulation

degradation, overheating, partial discharge activity, and mechanical

stress.

This approach significantly reduces unplanned downtime and improves

asset lifespan.

IoT Sensors & Real-Time Monitoring

- Oil Temperature & Oil Level Monitoring

- Load Current & Voltage Tracking

- Vibration & Mechanical Stress Detection

- Power Factor & Insulation Health Analysis

Data from these sensors is transmitted to centralized dashboards, providing operators with real-time alerts, health indices, and maintenance recommendations.

Digital Twin & Fleet Monitoring

Digital twin technology creates a virtual replica of transformers, allowing engineers to simulate load conditions and predict future performance.

- Identify high-risk assets

- Compare performance across substations

- Optimize maintenance scheduling

- Prevent cascading failures