AN END-TO-END SOLUTION

Our comprehensive transformer monitoring solution includes sensor deployment, real-time data acquisition, AI-powered analytics, and automated reporting. We provide both turnkey implementations for utilities and OEM integrations for transformer manufacturers.

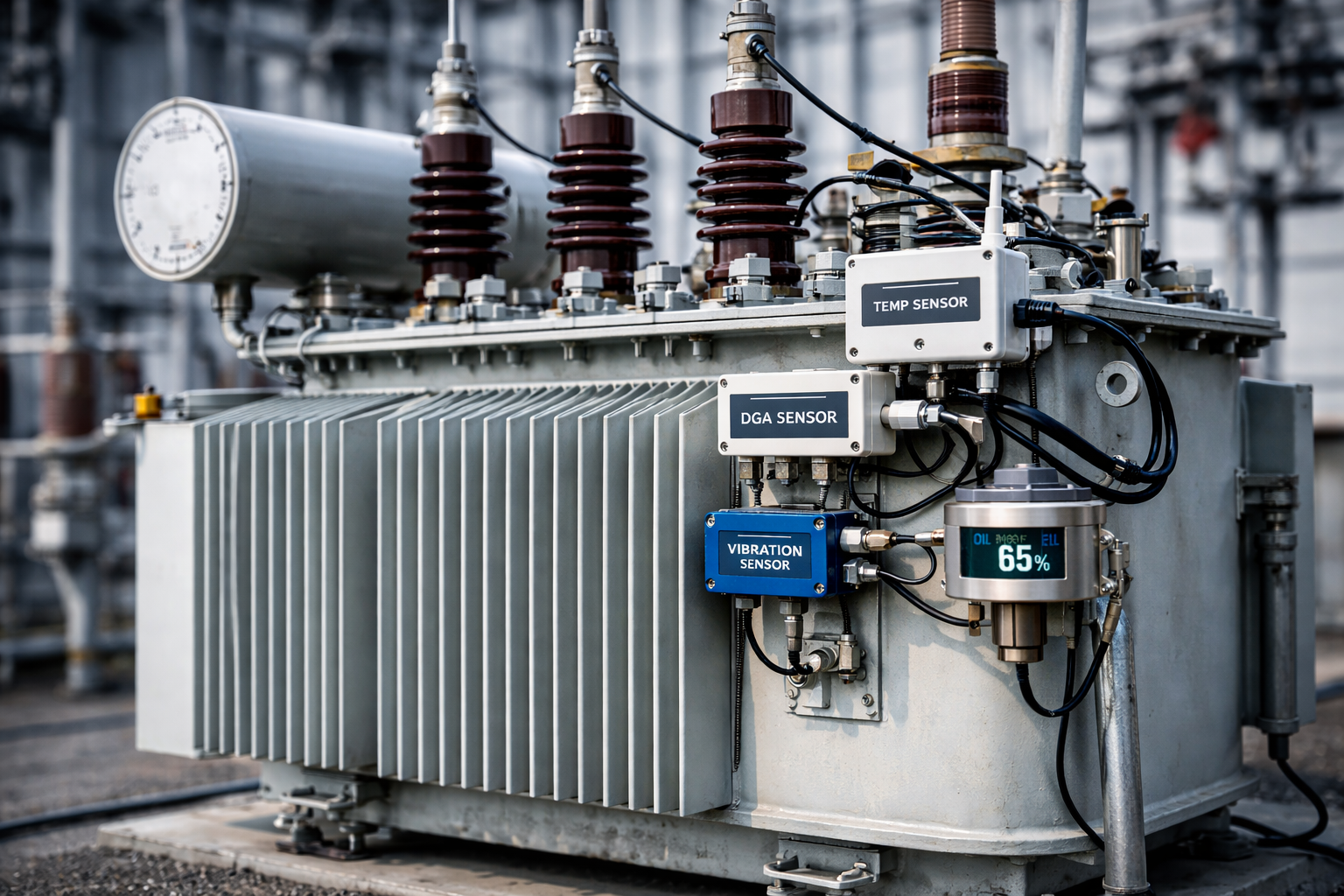

The platform continuously monitors critical parameters including oil temperature, dissolved gases, vibration, power factor, current, and voltage. Our machine learning models detect anomalies weeks or months before failure, enabling proactive maintenance interventions.

Data Collection & Collation

Wireless IoT sensors collect oil temperature, vibration, current, and voltage data every second. Edge gateways aggregate and transmit encrypted data to our cloud platform with military-grade security.

Analysis & Pattern Recognition

Advanced ML algorithms analyze historical and real-time data to identify fault signatures. Our models detect insulation degradation, winding deformation, core issues, and bushing deterioration.

Reporting & Visualization

Intuitive dashboards show transformer health index, parameter trends, and anomaly scores. Automated reports delivered daily/weekly via email. Export data in PDF, Excel, or CSV formats.

Enterprise-Grade Security

Personally identifiable facility data is fully encrypted and can be masked if required. The service is hosted on ISO 27001 certified cloud infrastructure with role-based access control and complete audit trails.

Our solution is highly generic and scalable - from monitoring a single critical transformer to an entire fleet of hundreds across multiple substations. We support industry-standard protocols including Modbus, DNP3, IEC 61850, and MQTT for seamless integration.

AI-Powered Intelligence

Each transformer's data is run through our advanced Machine Learning engine to build unique baselines and detect subtle deviations. We generate Health Index (0-100%), Remaining Useful Life (RUL), and Risk Scores based on multi-parameter fusion.

Contextual baselines - comparing against similar transformers, same manufacturer, or same age group - provide benchmarking insights. All reports are accessible via web dashboard or can be automatically emailed to stakeholders at configured intervals.

PRADJNA™ TRANSFORMER MONITORING PLATFORM

Intelligent Asset Management for the Modern Grid

For Talent Acquisition & Asset Performance

Transformer fleet management, as a function, today faces unprecedented challenges - aging infrastructure, increasing load demands, and limited maintenance budgets. Traditional time-based maintenance is no longer sufficient or cost-effective.

Pradjna™ provides a solution where currently there is a critical gap in predictive failure detection. By engaging with us, you gain the capability to identify developing faults weeks in advance, prioritize interventions based on criticality, and extend transformer lifespan by 5-10 years.

Key Differentiators

- Multi-parameter fusion: Not just DGA - we combine electrical, thermal, and mechanical data

- Self-learning AI: Models continuously improve with more data

- Non-invasive: Wireless sensors, no downtime for installation

- Proven ROI: 70-80% reduction in unplanned outages

SaaS / PaaS Model

Flexible subscription with per-transformer monthly pricing. No upfront CAPEX, includes all software updates and AI model improvements.

Usage-Based Pricing

Pay-as-you-go for low volume monitoring. Annuity-based enterprise plans for high volume, multi-site deployments with dedicated support.

OEM Integration

Embed our analytics into your transformer monitoring systems. White-label solutions available for manufacturers and system integrators.

Ready to transform your transformer maintenance?

Join leading utilities and industrial facilities that trust Pradjna for predictive transformer monitoring.